I. Introduction to the enterprise

Wuxi Best Precision Machinery Co., LTD., founded in May 1997, is a high-tech enterprise in Jiangsu Province. The main business of the company is R & D, production and sales of various precision parts and fixture products. The main products of the company are turbocharger precision bearing parts, turbocharger impeller, turbocharger intermediate housing, engine cylinder and other key automotive parts, seat components and other aircraft cabin parts and fixture for automobile, rail transit and other fields.

The company also uses its technological strength in precision parts processing and the flexible processing capabilities of automated production lines to supply precision parts to advanced manufacturing sectors such as pneumatic tools and refrigeration compressors. At the same time, the company's fixture business has been extended to automobile, aircraft and other fields of automatic production line manufacturing field. The company has been awarded the honorary titles of Jiangsu High-tech Enterprise, Jiangsu May Day Labor Award, Jiangsu Famous Trademark, Jiangsu Provincial Enterprise Technology Center, Jiangsu Provincial Informatization and Industrialization Integration Demonstration Enterprise, Wuxi Top Ten Private Enterprise and so on. In 2013, the company was awarded Jiangsu Province Industrial Design demonstration Enterprise, in 2014, Jiangsu Province management innovation enterprise, the company's products won the national key new products and Wuxi City Science and Technology Progress Award. In 2015, the company's advanced equipment and parts intelligent production workshop was awarded Jiangsu Province Demonstration intelligent workshop. In 2017, the Jiangsu Provincial government awarded Wuxi Best the "Outstanding Contribution Award for Manufacturing in Jiangsu Province".

Second, the challenges we face

In 2015, Suzhou Hangruicheng was fortunate to participate in the construction of Best intelligent workshop, and cooperated with Best to make intelligent manufacturing transformation of the whole machining workshop. The workshop has hundreds of advanced machining centers, mainly producing automotive turbocharger parts, production batch is very large, complex processing technology, high quality requirements. So there are many types of cutting tools, and the consumption is huge.

Before the tool management using manual accounting, manual statistics, old for new, employees own knife to knife mode, but in the face of 24 hours of production workshop production, tool use a huge number of manual management can not meet the needs of management. Problems such as discrepancies in monthly inventory accounts and unattended management and control of night shift are very prominent.

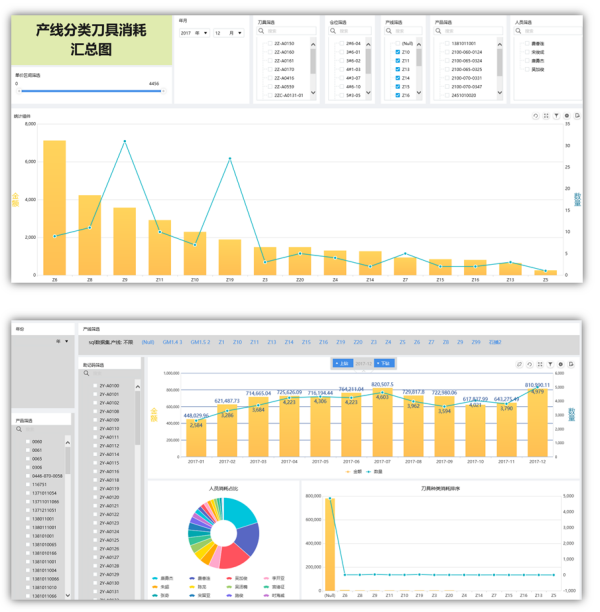

The management of tool actual consumption data, machine tool, work order, product processing consumption of tool cost, quantity, completely blank, only ERP management ledger, but the detailed tool cost, classification did not cover.

Iii. Brief introduction of Project construction

During the planning and construction of intelligent manufacturing workshop, Best sorted out the whole machining and manufacturing process and integrated the whole system of ERP, MES, intelligent tool cabinet system, tool setting instrument, machine tool data acquisition, etc. The tool pipe system of the whole process from ERP work order, intelligent tool cabinet work order leading tool, tool setting instrument matching tool, RFID chip data flow to machine tool complement, tool life collection and record, tool life expiration reminding tool change, smart tool cabinet replacing old tool with new.

Iv. Introduction to the use of intelligent tool cabinet

In 2016, 2 sets of Hangruicheng intelligent cutting tool cabinet were adopted, and the feedback effect was very good. In 2017, 4 sets were added, and so far, the customer feedback is very good! It is also well received by a number of customers who visit and exchange!

Smart tool cabinet scene picture:

Image of ERP system directly sending material request to intelligent tool cabinet:

Workers on site knife operation interface:

Tool statistical analysis report:

|

15050151202 Free service hotline |

|

Follow us Please scan the official account |

Copyright ? HRC Automation(Suzhou)Co.,Ltd 備案號:蘇ICP備19026496號